Human resources are given the highest priority among all resources in the manufacturing world even before financial resources. It is because people are the primary resources for any manufacturing establishment.

Since the beginning of the era of industrialization, human capital has been considered a crucial and valuable asset in all industries, including manufacturing. In today’s competitive world, organizations invest in developing their employees for optimal output, making employee retention a fundamental requirement for any institution.

In Nepal, there are two major factors contributing to brain drain. First, the government’s policies play a significant role as they engage in bilateral labor agreements with wealthy countries, aiming for brain exchange in exchange for remittances. Second, the allure of new technology, attractive lifestyles, and improved financial prospects globally are known to attract skilled individuals.

Currently, Nepal is facing a deeper economic downturn that began with the onset of the Covid-19 pandemic over three years ago. Initially, the slowdown affected specific groups and sectors, but later on, spread throughout the entire business community. While we won’t delve into the reasons behind the economic slowdown, it is important to consider this situation while talking about the current state of the Nepali manufacturing sector.

Currently, Nepal is facing a deeper economic downturn that began with the onset of the Covid-19 pandemic over three years ago. Initially, the slowdown affected specific groups and sectors, but later on, spread throughout the entire business community. While we won’t delve into the reasons behind the economic slowdown, it is important to consider this situation while talking about the current state of the Nepali manufacturing sector.

As manufacturers, let us first examine the country’s immigration data. According to the Department of Immigration’s 2022 records, approximately 3,000 Nepalis leave the country through Tribhuvan International Airport every day, either as migrant workers or students going abroad for their further studies. There might not be any systematic data available for Nepali nationals immigrating to India.

Now, from the human resources management perspective, there is one category of students who migrate from Nepal with a rare possibility of returning and finding suitable employment. On the other hand, engineers, doctors, and trained professionals are migrating to other countries in significant numbers, with very few actions or efforts toward their retention.

Nepali manufacturers are currently facing two distinct challenges in the market. First, due to the prolonged period of low business volume, survival becomes a struggle, resulting in constant financial limitations. Consequently, it becomes difficult to allocate significant resources to employee motivation and retention. In such cases, self-retention techniques should naturally come into play, but in the context of Nepal, they are ineffective due to the overwhelming outward flow of talent.

Why are employees not satisfied with their current jobs? This is a crucial subject of study. Let us discuss a few parameters, focusing on traditional topics that require attention:

- Monotonous work

- Job insecurity

- Demanding workload

- Poor communication

- Bad relationships with colleagues

- Lack of control over workload and schedules

- Long hours and tight deadlines

Typically, the Human Resources departments in the organizations focus on training and counseling sessions but often fail to generate positivity within the workforce. These sessions tend to focus more on skill development, overshadowing overall employee satisfaction and needs analysis. This approach dominates HR activities in Nepal under the guise of corporate culture. HR departments in organizations should be discerning and mindful.

Here are some additional areas to consider:

- Weight of job responsibilities

- Unsafe work conditions

Together, as manufacturers, we need to improve workplace happiness to retain employees to some extent.

Major Mistakes of Manufacturers

One key aspect is that most owners of small and medium manufacturing companies take local employees for granted and assume that they are satisfied with a nominal salary simply because they have a job in their hometown and can be with their families. However, this sentimental judgment is no longer true. It is the manufacturer’s biggest mistake, as all efforts invested in developing unskilled workers into skilled manpower can go to waste over time. Therefore, dealing with employees in a professional manner becomes more significant, leading to greater satisfaction. Offering competitive salaries plays a vital role in employee satisfaction and presents the biggest challenge for manufacturers.

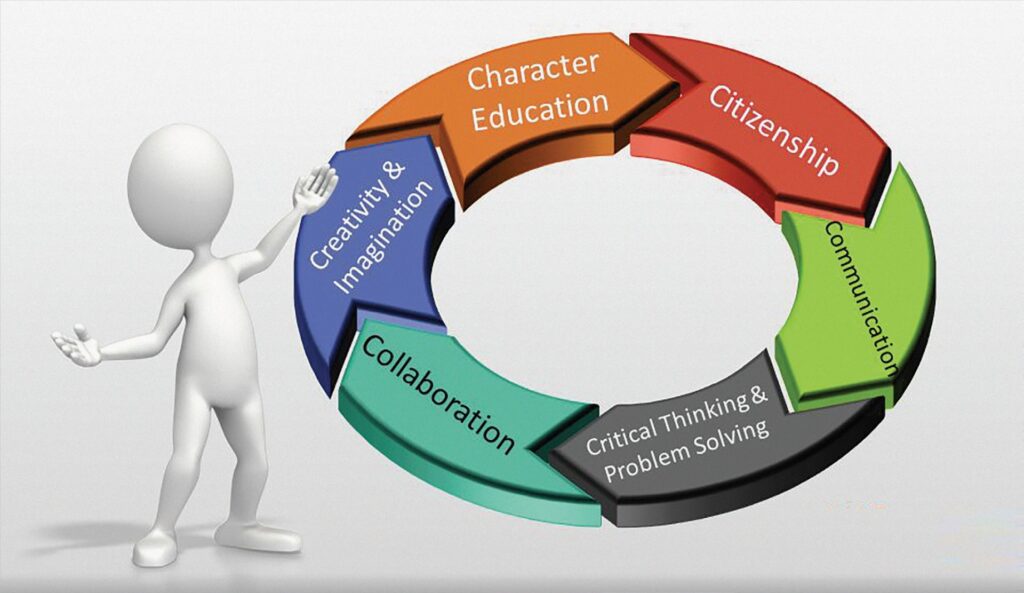

The most significant challenges and opportunities for Nepali manufacturers lie in incorporating the following six elements into our organizations to improve employee comfort:

- Inclusion

- Appreciation

- Support

- Trust

- Purpose

- Achievement

If the organizations genuinely focus on these areas, positive workplace well-being will be reflected. In the present context, recruitment and preparation, unconscious bias in hiring, and relying solely on recommendations or salary as the hiring criteria will not yield desired results in Nepal.

In conclusion, organizations need to strive for developing disciplined employees, make them accountable, and create an environment of trust and faith. There should be open communication regarding the requirements and needs of the staff and the senior management need to work for fostering inclusivity in the workplace, and allow employees to engage in non-work-related conversations from time to time. Staff appreciation and recognition should be given priority. A clear vision of responsibilities and tasks, along with recognition and appreciation, can make a significant difference in employee satisfaction.

Baral is the CEO of Eco House, a group of companies working in manufacturing, construction, and trading. He is an MBA in Human Resource Management.